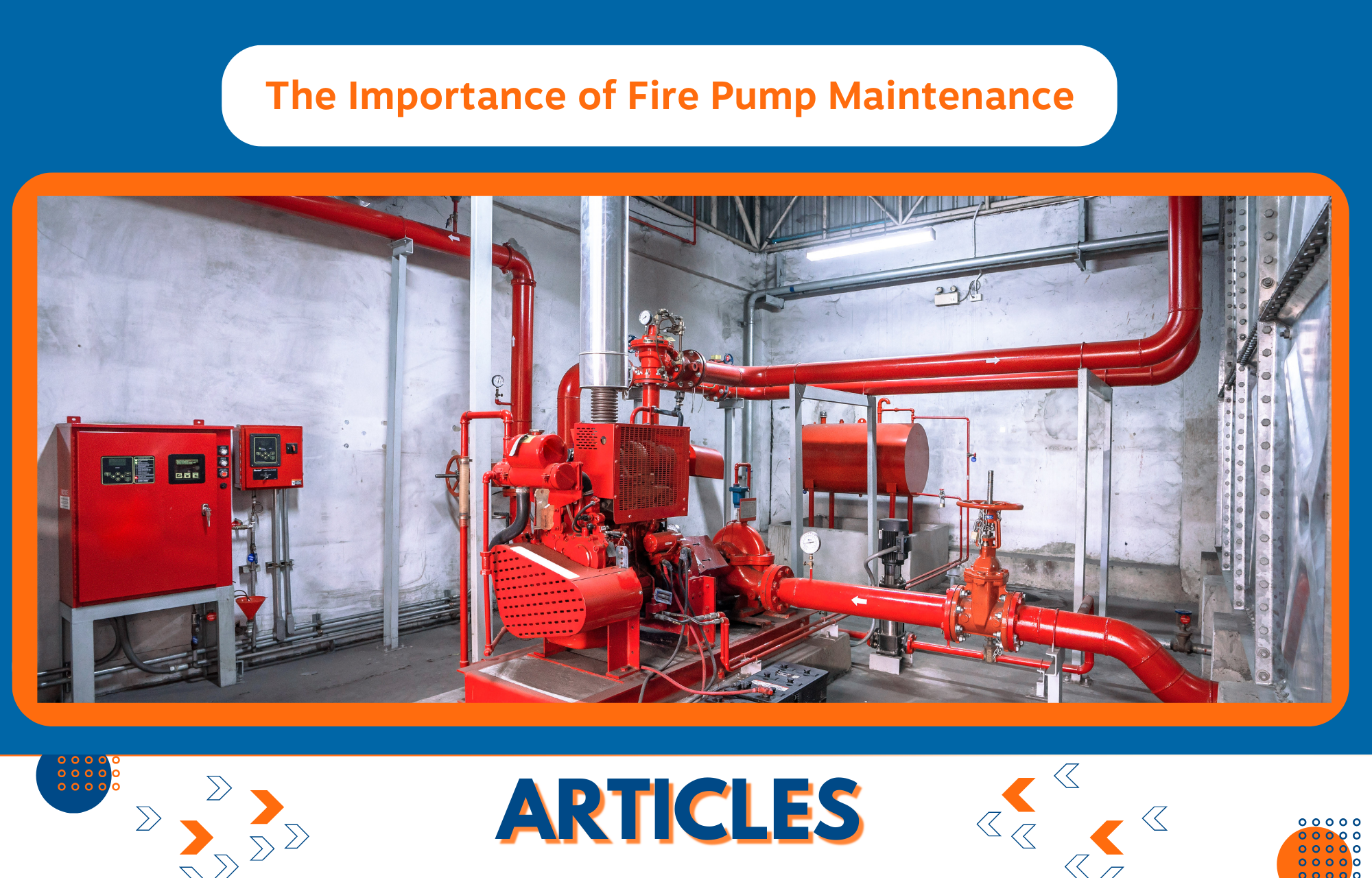

Any good fire protection system’s lifeblood is fire pumps, which guarantee a consistent water flow to fight flames. In homes, businesses, and factories alike, regular maintenance of these pumps is not only required by code but also a crucial safety precaution. Effective maintenance of fire pumps guarantees the best performance, increases the lifetime of the equipment, and assures that the system will operate as it should in an emergency. Ignoring maintenance can cause system breakdowns, endangering people, property, and companies. To find and fix such problems before they become significant, regular inspections, testing, and certified expert servicing are absolutely important.

Though sprinklers save lives, not every building has them, given the overwhelming evidence. The National Fire Protection Association (NFPA) reports that sprinklers extinguish 92% of fires big enough to cause activation. Furthermore, homes with sprinklers had an 87 percent lower death rate of building inhabitants in a fire than those without automated extinguishing equipment. Nursing homes and hospitals are the most likely places to find sprinkler systems (67%), with businesses coming in second (8%) and houses coming in last.

Why is maintenance on a fire pump required?

Many people believe that the most important part of a water-based fire prevention system is a fire pump since, without a fully operational pump, water-based systems cannot be used. Finding that a fire pump is not operating as it should can be disastrous when a fire strikes large areas with high risk threats. The condition of the components of the fire protection system should be constantly checked and tested, as this piece of equipment is rarely used. This is true, especially more so for the actual fire pump.

The performance of the fire pump is absolutely vital in places where water is delivered from it. Water-based systems cannot contain fires as they are meant to without enough pressure. This can produce disastrous outcomes. Given the rather large initial outlay of a fire pump, maintenance and protection become even more crucial. If the correct actions are taken, fire pumps are built to last for long life cycles. The lifetime of the fire pump depends critically on establishing and regularly sustaining a regular inspection cycle.

If neglected, though, some of the primary causes of pump breakdown are:

Misapplication of the pump: a good task depends on the appropriate application of the pump. Here, the secret is complete site and system information paired with product understanding. The aim is to choose the right pump to run at the maximum efficiency point for the needed flow. The correct material must be used to build the pump system if it is to withstand damage and too much wear from the product being pumped.

Deadheading a pump: When a pump is deadheaded, the heat that the recirculating product produces in the pump end under pressure can seriously harm mechanical seals and wear components. From a clogged discharge line to trash caught in the impeller to a vacuum leak in the suction line, various things could be responsible here.

Improper service: A good service program and finishing necessary repairs at the time of service top the list for assuring a piece of equipment can run through the task from start to finish. Ignoring service intervals can rapidly transform a little investment into a large outlay. Whether they are on the road or in the shop, mechanics must use service tools to find issues, resist short cuts, and perform the necessary repairs.

Solids passing the pump: materials can find their way into the suction line and into the pump ends even with the best attempts. Most likely the most destructive and capable of causing extreme damage—such as shattering an impeller—are rocks and metal pieces of any kind. Particularly in non-solids handling pumps, it is crucial to know ahead of time what is probably passed through the pump and use the suitable size hole screen or strainer; also, keep the suction intake raised from the bottom of the suction point.

Keeping Your Fire Pump in Working Order

Reviewing your local codes as well as the NFPA testing and inspection standards comes first. You should get in touch with a professional or one of your employees educated to handle this particularly. Tell any relevant stakeholders—such as the fire department, on-site employees or security guards—about testing so they can get ready. All pumps, whether electric or diesel-fueled, should be tested weekly and monthly for both automatic starting and flawless operations (without water), as well as any outside obstacles that can compromise performance.

You will look for:

- System suction and discharge pressure readings

- Outlets and leaks

- Any odd vibrations or sounds?

- Packing boxes, bearings, or pump casing to ensure they’re not overheating

- Areas requiring replacement or enhancement

- The time the motor takes to attain maximum speed and any following actions

- Check the diesel pump’s operating oil pressure gauge, water, and oil temperatures, as well as the engine’s time to crank and reach running speed.

To guarantee that the pump is allowing the right water flow, you should also do more thorough checks yearly using water.

Specific Situations

Fire pump maintenance and testing will vary from structure to structure since every system is unique and no one-size-fits-all solution or schematic works everywhere. A hospital building might use a different system than one containing highly explosive materials; the data farm of an IT corporation would want a different system than an elementary school. You will also want to include testing and adjusting your sprinkler system and pump in the plan if you are renovating or altering the function of various rooms in the structure, say if a file room becomes a break room.

Questioning whether your pump is fit for the task? Get assistance from a local fire marshal or professional inspector from Rotaflow Fire & Utility. To find out about other methods to make your building safer and guard its most valuable contents—the people inside—you may also speak with our agents.

Courtesy: Scott Kneiss, Fire Alarm Sales Representative, Fire Protection- Edmonton