INTRODUCTION: NFPA 13 requires that when retrofitting a backflow preventer into an existing sprinkler system, a thorough hydraulic analysis must be performed. This analysis includes revised hydraulic calculations, new fire flow data, and any modifications to the existing system to accommodate the additional friction loss due to the new backflow preventer. NFPA 14 does not require supervisory air on manual dry standpipes, but the technical committee is looking to address this issue in the 2023 edition of NFPA 14. NFPA 14 is proposing new requirements for supervisory air on all manual dry standpipe. This is a unanimous decision from the technical committee and if passed ballot, the next edition of NFPA 14 will require all manual dry standpipe to be supervised with air.

Section 27.1.3 does not require all items from the list to be submitted for shop drawing review. Chapter 29 is specific to modifications to existing systems. The pipe that is more than 12 feet is the perpendicular span or run between the two changes in direction and is included in the linear length to apply bracing. The figure in the annex (Figure A.18.5.7.2) does a poor job of visually showing the difference between two scenarios. Section 6.5.2 states that 5 gpm is added to the sprinkler demand to size the common supply piping, but not if provisions are made to prevent flow into the domestic water system upon operation of a sprinkler. A dwelling unit is defined in Section 3.3.4.

Question #1 – “Bucket Test” in lieu of Hydraulic Calculations

An existing system was installed in 2016 and includes an auxiliary antifreeze system protecting unheated garages. Although a backflow preventer was shown on the accepted plans, isolating the antifreeze system, the backflow preventer was never installed, and the original hydraulic calculations do not include the friction loss for the backflow preventer. The local jurisdiction is requiring the backflow preventer be installed, per the original plans; however, including the friction loss for this device means that the hydraulic calculations will not work. Also note that the existing antifreeze is a noncompliant “food-grade” solution which will be replaced with a listed antifreeze solution.

As the hydraulic calculation will not work with a backflow installed, is it permissible to simply flow the sprinklers in these garages into a barrel to determine if the garage sprinkler system will work?

No. The procedure you described—sprinkler(s) pouring into a barrel—is known as a “bucket test.” Bucket tests are not approved by NFPA 13 or any other NFPA installation standard, and they cannot be utilised to get around NFPA 13’s requirements for hydraulic calculations. NFPA 13 is explicit when installing a backflow preventer as a retrofit into an existing sprinkler system.

According to Section 29.1.3 of the 2019 version of NFPA 13 (and earlier editions with identical terminology), “a thorough hydraulic analysis must be performed” when a backflow preventer is being retrospectively placed in an existing sprinkler system. Included in this analysis are:

- updates to the hydraulic calculations

- new data on fire flow

- any changes made to the current system to account for the increased friction loss brought on by the new backflow preventer.

The aforementioned requirements cannot be substituted with a bucket test. The aforementioned hydraulic analysis must be finished. The system will need to be changed if the current arrangement cannot be made to function with the additional friction loss of the backflow preventer. It should be noted that the complete hydraulic analysis required by this section only applies to the affected system (garage systems), and it is not the intention to provide a complete hydraulic analysis of the entire existing system. Rather, the goal is to simply confirm that the additional friction loss through the backflow prevention device can be supported. This idea will be stated in an annexe section that will be included in the NFPA 13 edition of 2025.

NFPA 13 does not mandate the use of a backflow preventer with antifreeze solutions, although other health codes or the water authority may. An antifreeze loop like shown in Figure 8.6.3.1 of the 2019 edition of NFPA 13 may be suitable, depending on the system’s overall configuration. Antifreeze loop requirements are comparable to those in earlier versions of NFPA 13.

Question #2 – Hose Allowance and Strainer Requirements in NFPA 15

NFPA 15 does not give danger classes like NFPA 13 since spray systems protect many different types of equipment. NFPA 15 is often used when other standards, regulations, or project specifications demand it. Spray systems frequently come from a Hazard Analysis/Risk analysis. The density and the hose stream allowance are frequently stated in such standards or specifications because to the wide variety of applications.

The system design objectives would be one of the following depending on the specifications or requirements specified in the other standards:

- Extinguishment

- Management of Burning

- Exposure Defence

- Reduced Flammable Vapours

Only twice does NFPA 15 explicitly state that a hose allowance is necessary. The first is the need for a 250-gpm hose allowance for Belt Conveyor protection under the extinguishment aim. The other situation is the safety of transformers, which similarly calls for a hose allowance of 250 gpm.

In this situation, the project specifications or the applicable standard that mandates the installation of the spray system would need to specify if a hose stream was necessary.

When using nozzles with canals smaller than 3/8 in. or for any system where the water is likely to include obstructions, a system must use main pipeline strainers, according to NFPA 15 Section 6.4.6.1. Each nozzle with a water passage smaller than 3/16 in. needs its own strainer.

Installing strainers when the water source is raw or grey water is standard procedure. Although NFPA 15 does not specify where the strainer should be installed, it is best practise to put it upstream of the deluge valve if the water source is a raw water source.

Question #3 – Pendent Sprinklers vs. Upright Sprinklers

A new sprinkler system was recently installed in a dining area with a sloped ceiling and exposed wood deck. The installed sprinkler system consists of exposed branch lines with upright sprinklers.

The use of upright sprinklers is being questioned with the statement that pendent sprinklers will provide “better coverage.” Is there a valid reason to change the sprinkler heads to pendant orientation?

No. A pendent sprinkler would not be required or preferred in this situation due to the open structure, sloping ceiling, exposed steel pipes, exposed wood deck in an assembly room (dining hall), the NFPA 13, building code, and fire code.

In the 2016 version of NFPA 13, Section 8.4.1.1 permits either upright sprinklers or pendent sprinklers, Section 8.6 covers both, and several additional sections combine the requirements for both types of sprinklers.

In other words, rotating the existing upright sprinkler into the pendent position has no technical basis in terms of a design rule, hydraulic benefit, or hydraulic efficiency.

Question #4 – Manual Dry Standpipe and Supervisory Air

Chapter 5 of the 2016 edition appears too ambiguous as to if it is a requirement to include supervisory air on a manual dry standpipe. Does NFPA 14 require supervisory air in manual dry standpipes?

No, supervisory air is not necessary for manual dry standpipes according to the 2016 version of NFPA 14, Standard for the Installation of Standpipe and Hose Systems. The specifications in Chapter 5 are for dry valves placed on standpipe systems and are taken from NFPA 13, Standard for the installation of Sprinklers. For numerous cycles of standards, these criteria have been quite ambiguous, and the technical committee hopes to fix this problem in the NFPA 14 2023 edition.

Soon second draught of NFPA 14 will come to an end with new guidelines for supervisory air on all dry systems. The technical committee reached this resolution unanimously, and if it passes the vote, the next version of NFPA 14 will mandate that every manual dry standpipe be under air supervision.

Question #5 Existing Systems Modifications

On a project which the scope of work includes to relocate sprinkler heads, it is being requested that the working plans include all 47 items included in Section 27.1.3 of the 2019 edition of NFPA 13. This is the section pertaining to required information to be included on the plans. Many of these items are not applicable to this small renovation project. Is the intent of NFPA 13 to require all items in the list of 27.1.3 for sprinkler renovation projects?

No, according to NFPA 13, 2019 edition, all the materials in Section 27.1.3 are not required to be submitted for shop drawing approval. The standard only specifies which things from the list are pertinent to the design.

Working drawings must be drawn to the specified scale, on sheets of the same size, with a plan of each level, and they must include the elements from the following list that are relevant to the system’s design, according to Section 27.1.3. Many of the elements on this list would not apply to the design of a project to renovate an existing sprinkler system that only entails moving sprinkler sites.

Chapter 29 deals specifically with system changes. Both Section 29.1.2 and Section 29.6.1 provide that if an existing system is added to or modified, sufficient information about the current system must be shown on the drawings to make all circumstances obvious.

The AHJ has the discretion to interpret these clauses. However, the standard’s goal is that sufficient details be provided to appropriately describe the work being done and the related standard compliance.

Question #6 – Earthquake Bracing

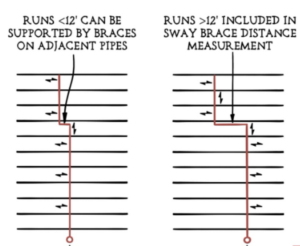

Section 18.5.7 of the 2019 edition of NFPA 13 speaks about runs of pipe between changes in direction but Figure A.18.5.7.2 shows the longitudinal bracing on the last piece of main. In this figure which pipe is more than 12 feet?

The pipe between the two direction changes in Figure A.18.5.7.2 that is longer than 12 feet is the perpendicular span or run. Where this span is greater than 12 feet, as mentioned in the main section (18.5.7.2), it is included in the linear length to apply bracing. The distance between changes in direction is not taken into account or applied when it is less than 12 feet.

Visually contrasting the two scenarios is difficult to achieve with the graphic in the annexe (graphic A.18.5.7.2). The figure is not meant to be a scaled depiction because of its extremely small size and lack of features. Although the longitudinal brace does show up where it does, the user is not given enough dimensions or information to completely comprehend the situation. The number just intends to highlight the fact that where the 12 feet difference is bigger, more bracing will be added. The longitudinal brace’s exact position in the diagram is irrelevant.

Question #7 – ICC-ES Evaluation Reports and Requirements for Pre-Fab “Pods``

The ICC Evaluation Services (ICC-ES) created a report (ESR-4445) that supports the omission of sprinklers in light and ordinary (group 1) occupancies for prefabricated enclosed booths or pods installed in otherwise fully sprinklered building. Can this report be used to omit sprinklers within the booth or pod without a specific omission in NFPA 13?

No, none of the NFPA 13 technical committees take into account ICC-ES Evaluation Reports (ESR) when they are released by the ICC. An ESR is not permitted to alter or apply exceptions to the NFPA 13 standards that the model codes (IBC, IFC) relate to. This implies that an ESR cannot make an NFPA 13 exemption.

It specifically points the user to NFPA 13 for occupancy classes for ESR-4445, an enclosed booth that doubles as a room, and it directs the building official to Section 903.3 for NFPA 13 compliance. A building authority may exclude sprinklers in this area with an engineering analysis, according to ESR-4445 Section 5.5. Since the building official is instructed to consult NFPA 13 to determine whether the area is a light hazard or an ordinary hazard, it would be highly challenging to defend an unsprinklered booth or room in a sprinklered structure under the ESR’s current wording. When there is no exemption for such a booth or room, the reference to Section 903.3 instructs the building authority to adhere to the standard. The booth is not justified in this section until #2 is utilised and permitted by the fire code official, despite the fact that the building official may use Section 903.3.1.1.1 for exempt sites.

Small temporary inhabited enclosures (booths), which are under 24 square feet in size and do not extend to the ceiling, are permitted by NFPA 13 Section 9.2.10 for the 2022 edition. Although the area exemption is not in compliance with the booths in this ESR, the height exception is. In conclusion, sprinkler protection for these booths was addressed by the NFPA 13 technical committees. In order for any compromises to be valid, a building must be completely sprinklered in accordance with Section 903.3 of the IBC.

Question #8 – Extra high ceilings and Density Increase

A project consists of 53 ft. ceilings over injection molding and the sprinkler criteria is proposed to be Extra Hazard Group 1 (EH1). Additionally, there are areas of solid pile plastic storage to approximately 20 ft.

Should the density be adjusted beyond EH1 to account for extra high ceiling protection over EH occupancy? It appears the roof/ceiling height is restricted to 35 ft. in accordance with the 2019 edition of NFPA 13

For non-storage uses, there are currently no obligations to raise the design standards for high ceilings. For high-piled group plastic storage density space criterion (see Table 21.3.3(a)), the maximum ceiling height is given as 35 feet; however, the Extra Hazard Group 1 criteria used for non-storage rooms does not have a maximum ceiling height. Numerous successful experiments conducted

during the development of sprinkler standards have proved that sprinklers are efficient and would operate as intended at ceiling heights up to 60 feet; however, more recent testing has produced different findings. Test results for sprinkler application in non-storage occupancies with high ceilings are shown in publicly available reports. These experiments indicate that for some ceiling heights, an increase in density could be necessary.

Although NFPA 13 does not currently call for any modification, these discoveries are being explored as the 2025 edition of NFPA 13 is being developed.

Question #9 – Minimum distance from FDC Check Valve to Exterior

The 2016 edition of NFPA 13 specifies that for drains subject to freezing, there is a required minimum distance of 4 ft. of exposed pipe between the drain valve and the exterior.

Is there a similar requirement for a minimum distance for a FDC line from the check valve to the exterior?

No. The distance between the check valve and the FDC is not required to be a minimum prescribed distance. A.8.17.2.4 of NFPA 13’s annexe note does mention that the check valve should be placed in an FDC line to “minimise freezing potential.” Additionally, in locations prone to freezing, Section 8.17.2.6 mandates the installation of an automatic drain valve in the pipe between the check valve and FDC.

Because different regions have different requirements for temperature and freeze protection, the standard intentionally leaves the criterion ambiguous.

Question #10 – Fire Department Connections – Siamese vs Single Inlet

Typically, fire department connections (FDC) for a sprinkler system consist of 2 – 2 ½ inlets (Siamese). On a recent project, a single system with a 2 ½ inch riser was shown with a single inlet fire department connection. We understand that

Section 8.17.2.3 does allow hydraulically calculated systems to have an FDC size equal to the largest riser.

Is it a requirement of the 2016 edition of NFPA 13 to have a Siamese type fire department connection?

No, 2-2 12 inch outputs are not necessary for an FDC linked to a single system through a 2 12 inch riser.

Single-outlet fire department connections are allowed when piped to a 3 inch or smaller riser, according to Section 6.7.1.3.

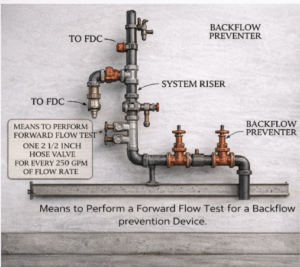

Question #11 – Means to Perform a Forward Flow Test for a Backflow prevention Device.

It is understood that NFPA 13 requires a “means to perform a forward flow test.” NFPA 13, however, does not seem to have a lot of information on how to size the forward flow test connection.

How should this means be sized?

In the past, NFPA 13 merely required a method to be given and did not specify a size for the test. The “means” for forward flow testing must, however, be able to flow at the minimum flow rate required by the system demand, including any appropriate hose stream allowance, according to NFPA 13.

The specifications for this test have been refined throughout time according to NFPA 13. Since 1996, NFPA 13 has mandated the use of a method for performing the forward flow test and has offered recommendations in its Annex on how to do so, including the use of test headers, a bypass through the FDC with a closed valve, and closed loop flow with a metre or sight glass.

Table 8.16.2.4.2 on the size of main drains was changed in the 2016 version of NFPA 13 to permit main drains greater than 2 inches. This was done, as stated in the annexe to this section, so that the main drain would be able to flow at a rate that would meet system demand and provide a “practical means for performing the forward flow test of the backflow device.” There was no sizing advice added. The paragraph indicating that the means must be provided such that the system does not need to be taken out of operation in order to execute the forward flow test was elaborated upon in the 2019 version of NFPA 13. In the newly added Section 16.14.5.1.1, it is stated that the forward flow test equipment must be “serviceable without requiring the owner to modify the system to perform the test.”

For every 250 gpm of system demand flow rate, including hose allowance where appropriate, a 2 12 inch hose valve must be provided, according to the 2022 edition’s Section 16.14.5.1. Other methods are permitted under this section as long as the flowrate criterion is fulfilled and the system doesn’t need to be modified to carry out the test.

Question #12 – Water supply for NFPA 13D

A residential fire sprinkler system is being installed in a single-family home in accordance with the 2016 edition of NFPA 13D. The sprinkler system and the plumbing system will be separate but share a common water service. Is the domestic demand required to be added to the sprinkler demand as they are both served by a common water supply?

As long as the home sprinkler system only serves one dwelling unit, domestic demand is not included to the sprinkler demand.

However, the restrictions of Section 6.5.2 would apply if the sprinkler system serves more than one dwelling unit (and the sprinkler system and domestic usage are serviced by a shared supply pipe). According to Section 6.5.2, the demand for sprinklers is increased by 5 gpm in order to size the common supply pipe.

The 5 gpm is not necessary to be added, according to this clause, provided measures are taken to prevent flow into the household water system when a sprinkler is activated. Also take notice that Section 3.3.4 defines a residential unit.

Courtesy: Roland ASP, CET NFSA Technotes (Best of May 2022)