Any design project for a water transport or distribution network necessitates hydraulic calculations to assess the hydraulic supply (Qh) at one or more consumption points and to determine the water pressure required to maintain the desired flow.

In the context of fire safety, hydraulic calculations are critical for evaluating the flow of liquids—typically through a piping network—to ensure that fires can be effectively controlled. These calculations help guarantee that adequate water supply and pressure are available at key points to support fire suppression efforts.

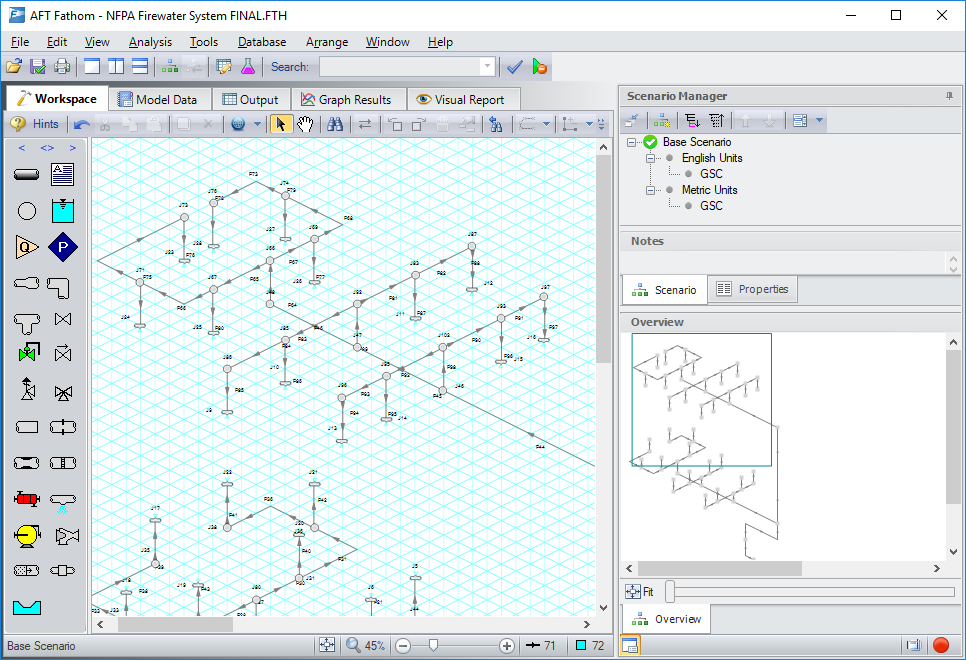

software for Pipe flow modeling

Hydraulic calculations are crucial for validating the flow of water—or water mixed with additives like firefighting foam concentrate—through piping networks designed for fire suppression and extinguishment. The comprehensive hydraulic calculation procedure is detailed in applicable model codes, such as those published by the NFPA.

These calculations offer a verifiable analysis of the three primary components of a fire suppression system:

- Water Delivery Requirements: Determining the amount of water needed to effectively suppress a potential fire.

- Available Water Supply: Assessing the sources of water that can be utilized during a fire event.

- Piping Network: Evaluating the configuration and capacity of the piping system responsible for delivering water when needed.

By thoroughly analyzing these components, hydraulic calculations ensure that fire suppression systems are both effective and compliant with safety standards.

Rotaflow uses AFT (Applied Flow Technology) Software to simulate and analyze such calculations , “TC Energy Firewater Pump House Sprinkler System Design”

AFT products are capable of hydraulically simulating a diverse array of industrial systems, including but not limited to:

- Power Generation Systems: Analyze fluid dynamics and thermal performance in energy production facilities.

- Chemical and Petrochemical Systems: Model the flow of fluids in various chemical processing applications.

- Oil & Gas Production, Transportation, and Refining Units: Simulate hydraulic behavior across the entire oil and gas lifecycle.

- Fire Suppression Systems: Evaluate the performance of firewater and foam systems for effective fire protection.

- Water and Wastewater Treatment Systems: Optimize flow and treatment processes in both municipal and industrial settings.

- Mining Processing and Support Systems: Assess fluid management and support infrastructure in mining operations.

These capabilities enable AFT products to enhance system design, efficiency, and safety across multiple industries.

AFT Fathom Software Products:

AFT Fathom offers the following capabilities:

- Modeling Incompressible Network Pipe Systems: Efficiently simulate and analyze fluid flow in incompressible piping systems.

- System Heat and Material Balance: Perform detailed assessments of heat transfer and material flow within the system.

- Steady-State Hydraulic Analysis: Conduct thorough hydraulic analyses under steady-state conditions to evaluate system performance.

- Cost Calculations: Generate cost estimates related to system components and operations.

Goodness and benefits AFT Fathom

Hydraulic simulation of the firewater systems using AFT Fathom enables our clients to:

- Assess System Compliance with NFPA Codes: Utilize the NFPA Reporting Tool to ensure the system meets all relevant standards and requirements.

- Evaluate the Impact of Modifications: Analyze how changes, such as the addition or removal of pipes, fittings, or nozzles, affect the overall pressure and flow demand of the firewater system.

- Identify System Bottlenecks: Detect areas of inefficiency within the system and explore strategies to enhance overall performance.